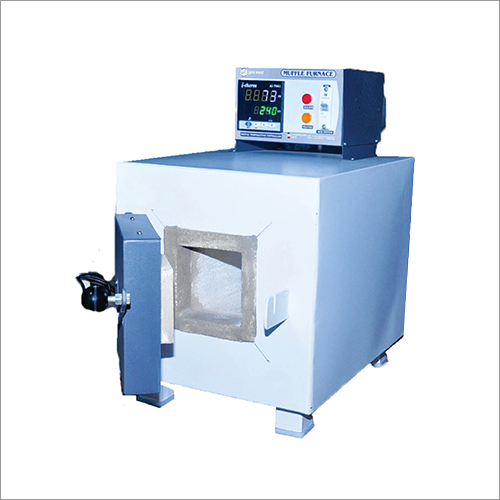

Electric Benchtop Muffle Furnace

Product Details:

- Condition New

- Usage Heat Treatment furnace

- Click to View more

Electric Benchtop Muffle Furnace Price

- 65000 INR/Unit

- 1 Unit

Electric Benchtop Muffle Furnace Specification

- New

- Heat Treatment furnace

Electric Benchtop Muffle Furnace Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cheque, Cash Advance (CA), Cash in Advance (CID)

- 2500 Unit Per Month

- 10 Days

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America

- All India

Product Description

To meet the variegated requirements of our customers, we have been a reputed supplier of Electric Benchtop Muffle Furnace in the market. It heats material without direct contact between the sample being heated and the flame itself. This is especially helpful in chemistry and material science labs to observe a materials behavior at high temperatures as the sample itself does not get destroyed. We have a large vendor base who serves us with their qualitative Electric Benchtop Muffle Furnace in safe packaging.

FAQs ofElectric Benchtop Muffle Furnace:

Q: What is an electric benchtop muffle furnace?

A: An electric benchtop muffle furnace is a conservative, tabletop-sized furnace that utilizes electric warming components to arrive at high temperatures in a controlled climate. It is regularly utilized for processes that require controlled warming, like strengthening, ashing, and sintering.

Q: How does an electric muffle furnace function?

A: The furnace comprises of a warming chamber (muffle) that is encircled by electric warming components. At the point when the furnace is turned on, the warming components create heat, which is moved to the muffle and the items inside it. The muffle forestalls direct contact between the warming components and the examples, guaranteeing uniform and controlled warming.

Q: How would I control the temperature in a muffle furnace?

A: Most present day muffle furnaces accompany computerized regulators that permit you to set and control the ideal temperature. You input the ideal temperature utilizing the control board, and the furnaces inside temperature sensor keeps up with the set temperature.

Q: What support is expected for a benchtop muffle furnace?

A: Standard upkeep could incorporate cleaning the inside after each utilization, really taking a look at the warming components for harm, and guaranteeing that the furnaces seals and gaskets are unblemished to keep up with temperature consistency.

Q: Might I at any point involve these furnaces for both limited scope and bigger scope tasks?

A: Indeed, benchtop muffle furnaces are reasonable for limited scope tasks, examination, and testing. Nonetheless, for bigger creation scale needs, you could have to think about bigger modern muffle furnaces.

FAQs of Electric Benchtop Muffle Furnace:

Q: What is the usage of Electric Benchtop Muffle Furnace?

A: The usage of Electric Benchtop Muffle Furnace is for industrial heat treatment processes.Q: What is the condition of the Electric Benchtop Muffle Furnace?

A: The condition of the Electric Benchtop Muffle Furnace is new.Q: Is the Electric Benchtop Muffle Furnace suitable for industrial applications?

A: Yes, the Electric Benchtop Muffle Furnace is designed for industrial use.Q: What type of heat treatment processes can be carried out with this furnace?

A: The Electric Benchtop Muffle Furnace can be used for various heat treatment processes in an industrial setting.Q: Can the Electric Benchtop Muffle Furnace be used for research and development purposes?

A: While its primary use is for industrial applications, it may also be suitable for research and development purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese